UPDATE: The CH-47

body is no longer available for online ordering. I'm

leaving these pages up for reference for modelers currently

working on this build. Please contact me with any

questions.

Click here for

assembly notes for the heli mechanics.

Click here

for assembly notes for the body shells.

Click here

for tips on assembling the engine pods.

Scale:

1/24

Rotor Span: 25.4"

Body Length: 25.6"

Weight RTF: 40 OZ

Here's

the

Chinook

ready for another sortie. The 'Hook is a modest-sized

and affordable project, but it's a little more challenging to

fly than most conventional tailrotor helicopters. The

complex drive train is also targeted toward more experienced

builders.

Here's the CH-47 on an early test flight. Note

the characteristic nose-high attitude in hover. The

Chinook was designed this way so that it would assume a level

attitude in cruising flight, making for a more comfortable

ride for the crew and passengers.

Here's another shot of the Chinook hovering on an

early test flight. Note that the rotors are synchronized

to be 90 degrees out of phase. The Chinook requires gyro

damping on both yaw and pitch, and four custom mixers control

lateral cyclic and DCP (differential collective pitch) on the

front and aft rotors.

Here's the Chinook climbing

out. The tandem rotor system is very efficient, and the

CH-47 hovers on just 10 amps of current.

This photo shows the Chinook with one body shell

removed. As you can see, the hardware installation is

pretty snug. The aluminum truss is the main structural

member, providing a frame for the helicopter mechanics and the

drive shaft that connects the two rotor systems

together. The truss is tilted 6.5 degrees relative to

the Chinook's body to give the two rotors their proper

orientation (this accounts for the 'Hook's characteristic

nose-high attitude in a hover). Power is provided by a

Scorpion HK-2221-12 motor, a Castle Creations Phoenix 35

controller and a 2200-3S lithium polymer battery.

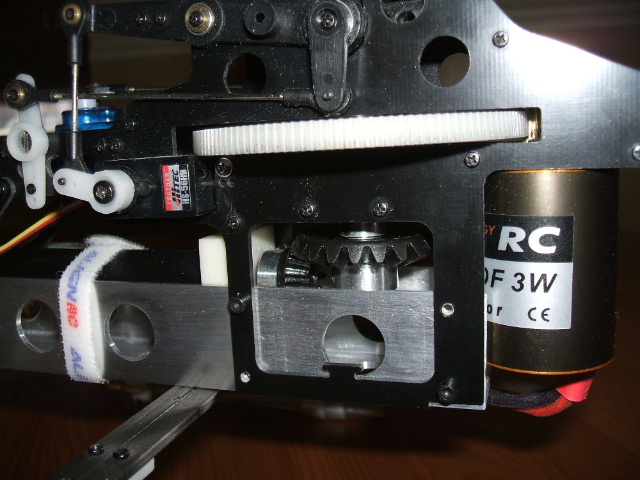

This

photo shows the CH-47's mechanics. I used crown and

bevel gears from the popular Corona 120 helicopter to

fabricate the drive shaft assembly. You can see that

the pitch servo pushrod has been screwed to a rigid post

to disable pitch input. Just two servos (roll and

collective) control each rotorhead. The fiberglass

side frames of the Revo-CP helis I used to build the

prototype made mounting them to the aluminum truss

relatively easy.